Features

- Low on odour

- Optimal Resistance properties

- Formulated with Low Toxic ingredients

- Wide range to cover various print requirements

Application

- Commercial/Packaging

Packing Type

- Plastic Pail

UV GP FLEXO GLOSS COATING

| Product | Viscosity (in Sec @ 30° C) | Curing | Slip | Gloss | Scratch |

|---|---|---|---|---|---|

| INSTACURE FC VARNISH | 42 ± 3 | 8 – 9 | 6 – 7 | 9 – 10 | 7 – 8 |

| IC UV PC PLUS VARNISH | 45 ± 3 | 8 – 9 | 7 – 8 | 9 – 10 | 8 – 9 |

| IC UV GLOSS COATER IN | 46 ± 3 | 7 – 8 | 6 | 9 – 10 | 7 |

| IC UV HVFC GLOSS RC VARNISH | 60 ± 5 | 8 – 9 | 7 – 8 | 9 – 10 | 8 – 9 |

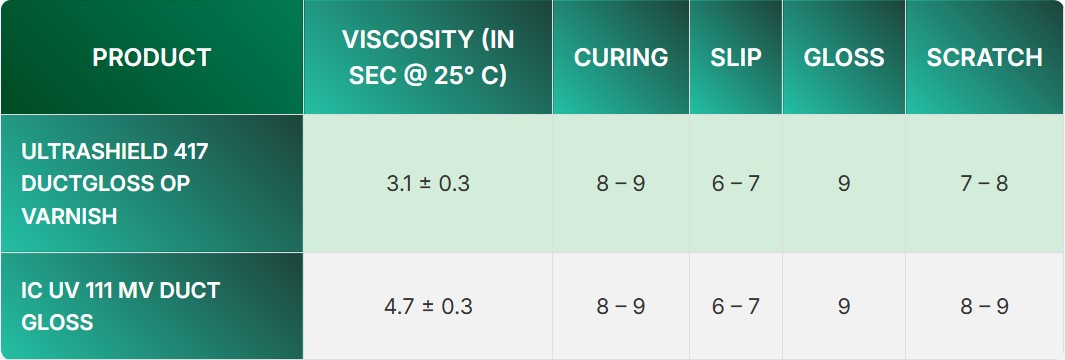

UV GP DUCT GLOSS COATING

| Product | Viscosity (in Sec @ 25° C) | Curing | Slip | Gloss | Scratch |

|---|---|---|---|---|---|

| ULTRASHIELD 417 DUCTGLOSS OP VARNISH | 3.1 ± 0.3 | 8 – 9 | 6 – 7 | 9 | 7 – 8 |

| IC UV 111 MV DUCT GLOSS | 4.7 ± 0.3 | 8 – 9 | 6 – 7 | 9 | 8 – 9 |

UV GP FLEXO MATT COATING

| Product | Viscosity (in Sec @ 25° C) | Curing | Slip | Gloss | Scratch |

|---|---|---|---|---|---|

| ULTRASHIELD 417 DUCTGLOSS OP VARNISH | 3.1 ± 0.3 | 8 – 9 | 6 – 7 | 9 | 7 – 8 |

| IC UV 111 MV DUCT GLOSS | 4.7 ± 0.3 | 8 – 9 | 6 – 7 | 9 | 8 – 9 |

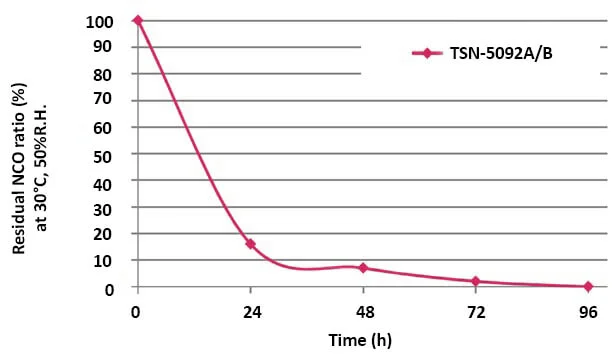

Curing Curve

Features

- Low on odour

- Optimal Resistance properties

- Formulated with Low Toxic ingredients

- Good grainy effects which cover various customer requirements

Application

- Commercial/Packaging

Packing Type

- Plastic Pail

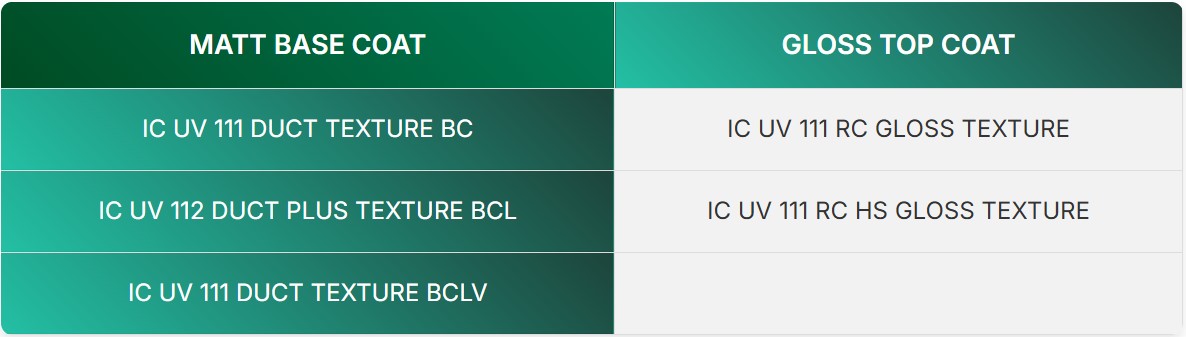

TEXTURE COATING – DUCT to COATER

| MATT BASE COAT | GLOSS TOP COAT |

|---|---|

| IC UV 111 DUCT TEXTURE BC | IC UV 111 RC GLOSS TEXTURE |

| IC UV 112 DUCT PLUS TEXTURE BCL | IC UV 111 RC HS GLOSS TEXTURE |

| IC UV 111 DUCT TEXTURE BCLV |

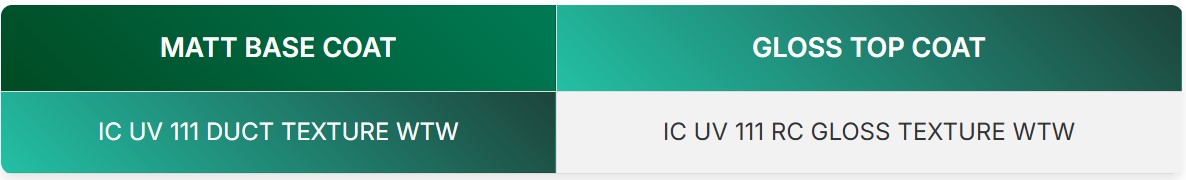

TEXTURE COATING – DUCT to COATER (WET to WET)

| MATT BASE COAT | GLOSS TOP COAT |

|---|---|

| IC UV 111 DUCT TEXTURE WTW | IC UV 111 RC GLOSS TEXTURE WTW |

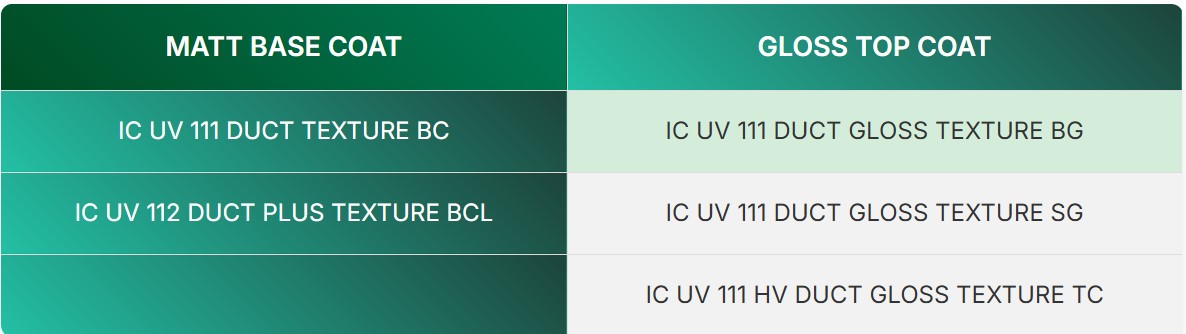

TEXTURE COATING – DUCT to DUCT

| MATT BASE COAT | GLOSS TOP COAT |

|---|---|

| IC UV 111 DUCT TEXTURE BC | IC UV 111 DUCT GLOSS TEXTURE BG |

| IC UV 112 DUCT PLUS TEXTURE BCL | IC UV 111 DUCT GLOSS TEXTURE SG |

| IC UV 111 HV DUCT GLOSS TEXTURE TC |